In the sealing industry, gaskets play a critical role in preventing leaks and ensuring stable performance. Among many materials, silicone gaskets have become the top choice for high-demand industries thanks to their reliable properties. But what exactly is a silicone gasket? Where is it used? And how do you choose the right type? This article will walk you through everything you need to know.

What Is a Silicone Gasket?

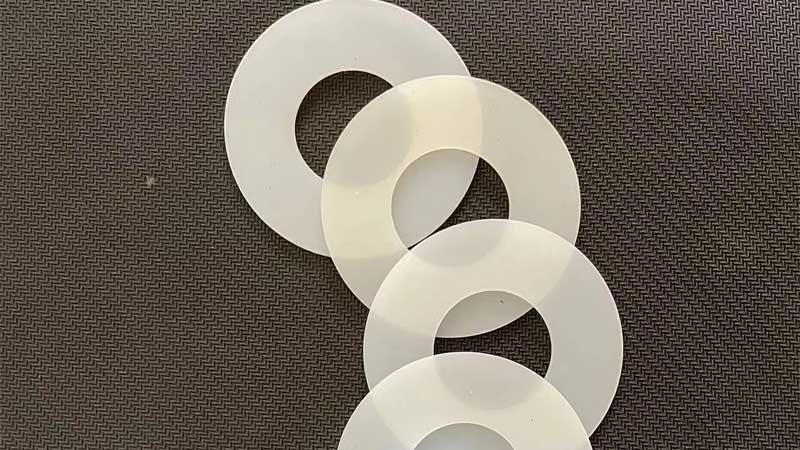

A silicone gasket is a high-performance sealing component made from silicone rubber. It’s designed to fill the gap between two or more contact surfaces, helping to block the entry or leakage of liquids, gases, dust, or fine particles. Beyond sealing, silicone gaskets also offer benefits like shock absorption, cushioning, and electrical insulation. They are widely used in industrial equipment and consumer products where stable sealing and protective performance are essential.

Compared to regular rubber materials, silicone gaskets stand out for their excellent resistance to both high and low temperatures, strong weatherability, biocompatibility, and lasting softness and elasticity.

What Are the Common Types of Silicone Gaskets?

To meet the sealing needs of different equipment, working conditions, and industries, silicone gaskets come in various forms. They differ not only in softness and material density, but also in their manufacturing methods and how they are used. Understanding these types helps ensure a better match for specific applications.

By Material Structure

- Solid Silicone Gasket: Made from dense silicone rubber, these gaskets offer excellent elasticity and pressure resistance. They’re ideal for high-strength sealing needs, such as flange joints and mechanical seals.

- Sponge Silicone Gasket: With a fine-cell internal structure, sponge silicone is soft and compressible. It’s suitable for flexible seals like door frames or cover plates, helping reduce vibration and noise.

- Foam Silicone Gasket: Similar to sponge silicone, but with even lower density. It’s ideal for light-pressure applications such as dust or moisture sealing, or for use as a cushioning material.

By Manufacturing Method

- Molded Gasket: Produced using compression molds, molded gaskets are best for custom shapes with detailed structures. They offer high dimensional accuracy and suit precision equipment.

- Die-Cut Gasket: Cut from silicone sheets using stamping or die-cutting, these gaskets are efficient to produce. They work well for flat, simple designs in high-volume applications.

- Extruded Seal Strips: Formed by extrusion, these continuous silicone profiles can be cut to any length. They’re widely used in linear sealing for doors, cabinets, and enclosures.

By Application Function

- Static Seal Gasket: Used in fixed positions with stable pressure and minimal movement. Common in flange connections or other static assemblies.

- Dynamic Seal Gasket: Designed to handle some level of movement, vibration, or repeated opening and closing. Found in keypads, appliance covers, and other parts needing better rebound and fatigue resistance.

How Well Do Silicone Gaskets Perform?

When choosing the right sealing material, performance under specific conditions is key. Silicone stands out among many sealing options thanks to its excellent temperature tolerance, chemical stability, softness, and regulatory compliance. Below, we’ll first look at the core strengths of silicone gaskets, then compare them with other common materials to help you better understand its position in the sealing industry.

Core Performance Advantages of Silicone Gaskets

| Property | Performance Highlights |

| Temperature Range | -60°C to +230°C; some high-temp grades can handle up to +300°C |

| Chemical Inertness | Resistant to most chemicals; safe for medical and food contact |

| Aging Resistance | Stands up to UV, ozone, and high humidity; does not easily crack |

| Electrical Insulation | Excellent dielectric strength; ideal for electronics and connectors |

| Softness & Recovery | Maintains shape and rebound over time; ensures long-term sealing |

| Certifications | Options available with FDA, LFGB, USP Class VI, RoHS, REACH compliance |

Thanks to these strengths, silicone gaskets work well not only in demanding industrial settings but also in fields like medical, food-grade, and electronics, where material safety and stability are critical.

Performance Comparison With Other Rubber Materials

To better understand how silicone compares, here’s a side-by-side comparison with some other popular rubber materials.

| Material | Temp Resistance | Chemical Resistance | Softness | Cost | Food-Grade Option | Recommended Use |

| Silicone | ★★★★★ | ★★★★☆ | ★★★★★ | Medium-High | Yes | Ideal for demanding applications |

| EPDM | ★★★☆☆ | ★★★★☆ | ★★★☆☆ | Medium | Some versions | Good for water sealing |

| Fluororubber (FKM) | ★★★★☆ | ★★★★★ | ★★★☆☆ | High | No | Best for heat and oil resistance |

| Nitrile Rubber (NBR) | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | Low | No | Budget choice for short-term use |

This chart shows that silicone may be more expensive than basic rubber, but it offers better heat resistance, softness, and chemical stability. That’s why it’s a top choice for high-performance sealing needs.

Which Industries Use Silicone Gaskets?

Thanks to their wide temperature resistance, chemical stability, and strong biocompatibility, silicone gaskets are a key sealing material across many industries. From precision medical devices to heavy-duty industrial machines, they perform reliably in demanding environments. Here’s an overview of typical applications.

Automotive and New Energy Vehicles

Silicone gaskets are widely used in both traditional fuel vehicles and electric vehicles:

- Engines and Transmissions: Seal areas like valve covers and oil pans, helping prevent oil leakage under high heat and pressure.

- Lighting and Electrical Systems: Provide waterproof, dustproof, and shock-resistant sealing for headlights and control modules.

- Battery Packs: Used around the edge of EV battery packs to meet IP67/IP68 standards, offering strong sealing and chemical resistance.

Key requirements: High heat resistance (150–200°C), oil resistance, anti-vibration, aging resistance.

Medical and Healthcare

Medical devices require sealing materials that are both safe and stable. Silicone gaskets are ideal:

- Medical Equipment: Seal critical interfaces in ventilators, infusion pumps, and diagnostic machines.

- Wearable Health Devices: Used in glucose monitors, ECG patches, and more, offering skin-safe sealing and cushioning.

Key requirements: Biocompatibility (meets USP Class VI and ISO 10993), non-toxic, and withstands repeated sterilization.

Food and Beverage

In food processing and kitchen equipment, silicone gaskets help ensure safety and hygiene:

- Food Machinery: Seal parts like pumps, valves, and filling lines that directly contact food.

- Kitchen Appliances: Found in coffee machines, thermos lids, pressure cookers, and more.

Key requirements: Compliant with FDA 21 CFR 177.2600, LFGB, and other food contact standards; resistant to heat, oil, and acid.

Electronics and Appliances

Silicone gaskets are widely used in both consumer electronics and industrial electrical systems:

- Consumer Devices: Seal inside phones, earbuds, smartwatches for waterproof and dustproof protection.

- Home Appliances: Used in ovens, dishwashers, and blenders.

- Industrial Electronics: Protect enclosures, outdoor LED modules, and sensors.

Key requirements: Heat resistance, IP67/IP68 waterproof sealing, flexibility, and strong insulation.

Aerospace and Industrial Equipment

Even in extreme environments, silicone gaskets remain reliable and durable:

- Aerospace: Seal aircraft cabin doors and electrical interfaces exposed to high heat and pressure.

- Industrial Machinery: Found in pumps, valves, and pneumatic or hydraulic systems for sealing and cushioning.

Key requirements: Withstand extreme temperatures and pressure, resist aging, last long, and maintain shape stability.

What Should You Look for When Choosing Silicone Gaskets?

When choosing silicone gaskets, there are several key factors to keep in mind.

Hardness (measured in Shore A) typically ranges from 30 to 80. A higher hardness means less compression and better wear resistance. Tensile and tear strength are also important, especially in dynamic sealing areas where durability over time matters. Look for a low compression set. This means the gasket can return to its original shape after long periods of pressure. Always check for relevant certifications, such as FDA, medical-grade approval, or UL 94 V-0 flame resistance, depending on your use case.

Conclusion

Silicone gaskets stand out for their well-balanced performance, material stability, and wide application range. They’re widely used in sectors like medical, food, and electronics. Whether you’re looking for strong resistance to temperature, long-term sealing performance, or certifications like FDA or USP Class VI, silicone offers a reliable and versatile solution.

If you’re developing custom products or have specific sealing needs, we’re here to help. Reach out to explore how custom silicone gaskets can meet your exact design and performance requirements.